Armored Fiber Optic Cable is a type of fiber-optic cable that has a protective metal armor layer to enhance its mechanical strength and safeguard the fibers from external damage. It is typically used in environments where additional physical protection is required, such as underground installations, power cable ducts, or areas exposed to external threats. The armored layer effectively prevents physical damage, aging, and corrosion, making the fiber optic cable more reliable and durable.

Types of Armored Fiber Optic Cables

Armored fiber optic cables can be classified based on two main factors: the material of the armor and the type of armor construction.

- Classification by Armor Material:

- Metal Armor Fiber Optic Cable:

These cables typically use steel wire or aluminum alloy as the armor material. Steel wire armored cables are the most common and provide high tensile strength and protection against piercing, making them suitable for harsh environments. - Non-metal Armor Fiber Optic Cable:

These cables use non-metal materials such as plastic or composite materials for the armor layer. They are generally used for lighter protection needs and cost less but do not provide the same level of mechanical protection as metal armor.

- Classification by Armor Construction:

- Longitudinal Armor:

In this design, the metal wire or strip armor is applied along the length of the cable. This provides uniform protection along the entire cable, which is ideal for environments with high mechanical stress. - Radial Armor:

Here, the armor is wound around the cable in a spiral or ring shape. Radial armor provides protection from punctures and is more effective in preventing environmental damage.

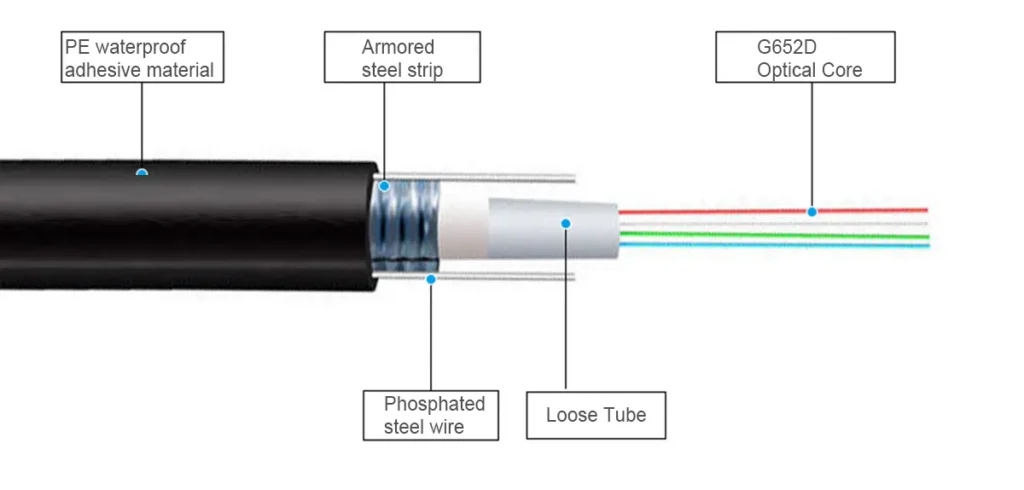

Structure of Armored Fiber Optic Cable

An armored fiber optic cable typically consists of the following layers:

- Fiber Core:

The fiber core is the central part of the cable that carries the light signals. It consists of one or more optical fibers made of glass or plastic. - Filling Material:

The filling material is used to fill the gaps between fibers, ensuring the stability and uniformity of the cable’s structure. This material is often non-conductive and provides moisture resistance and insulation. - Strengthening Layer (Strength Member):

This layer is typically made from non-metallic materials such as fiberglass or aramid yarn (Kevlar). It adds tensile strength to the cable, preventing the optical fibers from stretching or breaking under tension. - Metal Armor Layer:

The metal armor layer is the key feature of an armored fiber optic cable. This layer is usually made of steel wire or aluminum alloy, providing protection against mechanical stress, punctures, and physical damage. - Outer Jacket:

The outer jacket is the final protective layer that shields the cable from external environmental factors such as moisture, UV light, and physical damage. It is typically made from materials like polyethylene (PE), polyvinyl chloride (PVC), or other weather-resistant materials.

Functions of Armored Fiber Optic Cable

- Mechanical Protection:

The primary function of the armor is to provide protection against external physical forces such as crushing, stretching, puncturing, and rodent damage, ensuring that the fiber-optic core remains intact and functional. - Reliability:

Armored cables are more reliable due to their enhanced protection, especially in harsh environments or areas where cables are exposed to potential mechanical stress. They maintain stable data transmission even in high-risk areas. - Corrosion Resistance:

The metal armor, particularly steel or aluminum alloy, provides excellent resistance to corrosion, making armored cables ideal for use in underground, wet, or corrosive environments. - Environmental Suitability:

Armored fiber optic cables are well-suited for deployment in complex environments, including industrial settings, mining, oil platforms, and chemical plants, where high durability is needed. - Safety:

The armored design adds a layer of physical security, preventing tampering, damage, or sabotage. This makes armored fiber optic cables a good choice for sensitive or critical installations.

Applications of Armored Fiber Optic Cable

- Underground Fiber Optic Installations:

Armored cables are commonly used for underground fiber-optic installations to protect against physical damage, such as accidental digging or rodent attacks. - Industrial Control Systems:

In industries like oil and gas, mining, and chemical plants, armored cables provide reliable communication and data transfer in environments exposed to extreme conditions. - Submarine Cables:

Armored fiber optic cables are used for underwater installations, such as submarine communication cables, to protect the fibers from the harsh oceanic environment and physical impact. - Public Transport Systems:

In applications like railway or metro systems, armored cables are used for secure and reliable data transmission between communication devices, CCTV systems, and control centers, especially in underground and high-traffic environments. - Security and Surveillance Systems:

Armored fiber optic cables are used in surveillance applications to ensure the integrity of the data transmission between monitoring cameras and central stations, preventing tampering or damage to the cable.

Summary

Armored fiber optic cables are designed to provide enhanced physical protection for fiber-optic lines, particularly in environments where the cables may be exposed to mechanical stresses, punctures, or environmental hazards. They are widely used in underground installations, industrial systems, security networks, and high-risk environments. Their strength, durability, and reliability make them a critical component in ensuring secure and stable data transmission in challenging conditions.